Products

I. TECHNICAL PARAMETER

Voltage AC 380V 50Hz 3Phase 4Wire

Total Power 15kw

Air Consumption 200L/min

Air Pressure 0.5MPa – 0.8MPa

Weight Around 10t

Overall Size 13000mm×3900mm×3360mm/2500mm(Length x Width x Height)

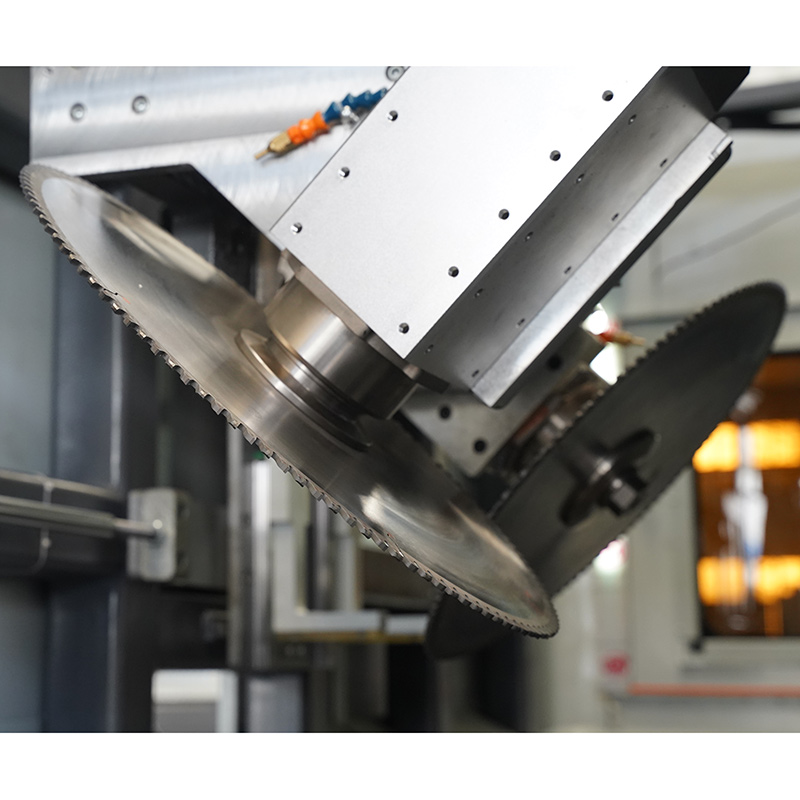

Blade Diameter Each Φ550(×2)

Blade Spindle Power 3.0kw 50Hz (Single)

Cutting Angle ±45° and 90°

45° Cutting Range 170x130mm(width × height)

90° Cutting Range 170x190mm(width × height)

Cutting Length 230mm(min. size is according to width)~6300mm

Length Precision ±0.1mm

Max. Length 6300mm

Profile Quantity in loading area 6 pieces

Cutting pieces per time 2 pieces

Feeding robot stroke 7360mm

Feeding Robot Speed 40m/min(0.67m/s)

Discharging Robot Stroke 750mm

Discharging Robot Speed 40m/min(0.67m/s)

Blade Vertical Running Speed 0~15m/min(0.25m/s)

II. Machine Features

1、Conveying Section

(1)Function

Robot Arm

- a. The X axis is driven by a Schneider motor with a reducer on a flat guide rail through gear and rack meshing. The stroke is 7360mm;

- b. The Y-axis and Z-axis are driven by servo and the stroke is 175mm;

- c. There are 2 robot arms in total, which can complete synchronous conveying of two materials, and can also convey single-line or double-line synchronously;

- d. The foremost pressure pliers of the robot arm can be selected and fixed at any angle through tapping and nut locking, which is convenient for clamping different materials

Lifting Frame

- a. The lifting and lowering of the lifting frame is realized by the simultaneous operation of the 4 cylinders underneath. Without ensuring the synchronization of the rise and fall of the 4 cylinders, the auxiliary parts CB are added to each cylinder to buffer them, and when they rise to the highest point and fall to the lowest point, the stroke of the cylinder is in the maximum and minimum limit states.

- b. The distribution of the rollers on the lifting frame, the closer to the machine head, the denser the distribution of the rollers, ensuring accurate and stable cutting.

- c. The altimeter is installed at the end of the conveying section to detect the height of the processed material, which facilitates the automatic and precise positioning of the saw blade, and improves the processing efficiency and processing quality .