Products

Features:

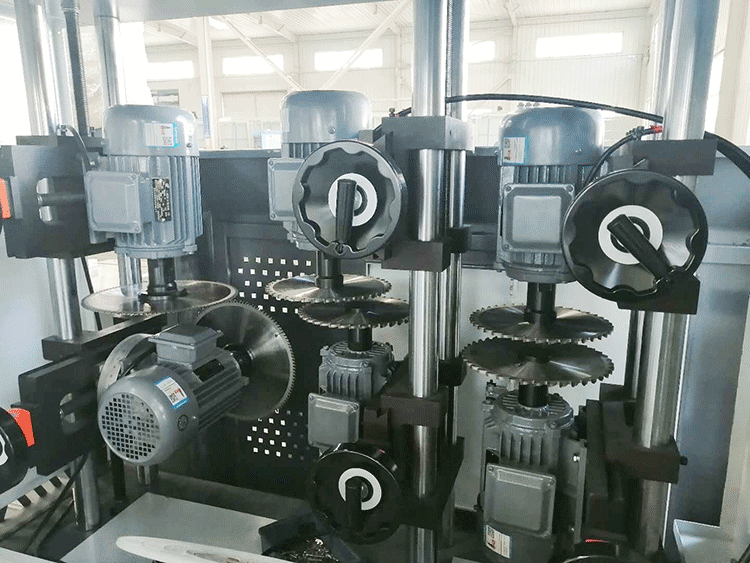

- This machine adopts cemented carbide disc milling cutter, which is self-made by our company according to cutting requirements. Special milling cutters can also be designed and processed according to user requirements.

- The special lengthening motor is connected with the blade for milling.

- The handle and lead screw are used to drive the movement of the horizontal or vertical rail to adjust the height and depth of the milling profile by the blade.

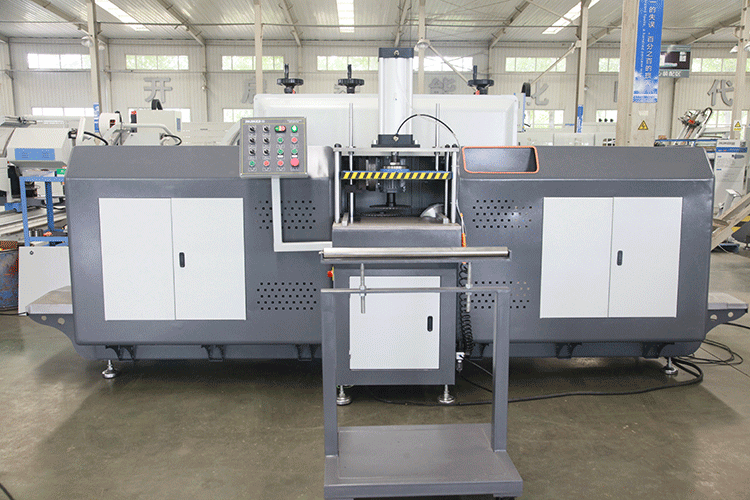

- The feed mechanism adopts a reducer motor to drive the lead screw, which can be adjusted by frequency conversion, which makes the cutting feed more stable, uniform cutting accuracy and good surface quality, protected by a protective cover, and high safety efficiency.

- The pneumatic control system realizes the spray control of work piece compression and cutting feed, simple operation, safe and reliable, and high production efficiency.

- 6.There is a compression cylinder with a diameter of 160mm on the fixed table where the profile is placed, which can clamp multiple profiles and is stable and reliable.

Parameters:

Power 380V 50HZ

Motor speed 2800r/min

Air pressure 0.5-0.8MPA

Quantity of and saw blades milling cutters 6 PCS (2 piecesΦ350 saw blades; 4 pieces Φ250 milling cutters)

motor power 2.2KW×6

Feed motor power 1.5KW

Motor spindle diameter Φ30mm

Saw blade Specification 350×3.5×30×Z100×2

Dimension 3850*2000*1900mm

Weight 1800KG